Products

Hydroxyl Terminated Polybutadiene

Hydroxyl-terminated polybutadiene (HTPB) is a form of liquid rubber with different molecular weight (approximately 1500–10,000 g/mol) and a high level of reactive functionality. The liquid rubber possesses a unique combination of properties including a low glass transition temperature, low temperature flexibility, high solid-loading capacity, and excellent flow ability. They have been widely used in adhesives, coatings, sealants, medicine, as well as energetic materials.

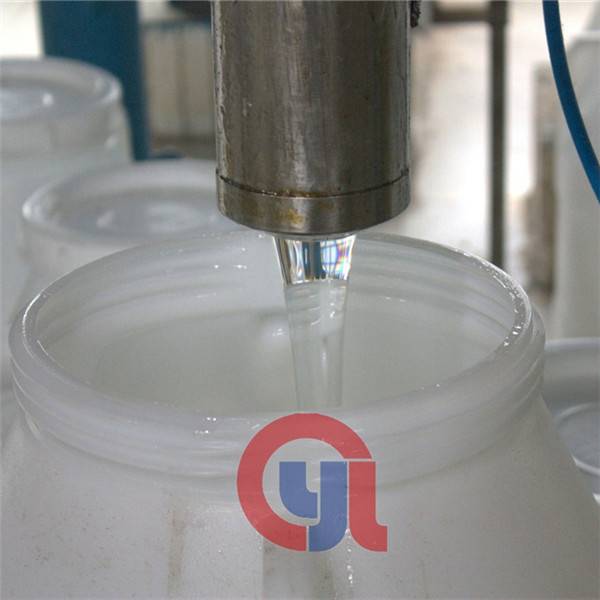

HTPB is a translucent liquid with a color similar to wax paper and a viscosity similar to corn syrup. The properties vary because HTPB is a mixture rather than a pure compound, and it is manufactured to meet customers’ specific requirements.

1. APPEARANCE:Colorless or yellowish transparent liquid

2. SPECIFICATION, Part I:

| PROPERTIES |

Specification |

|||

|

Hydroxyl content mmol /g |

0.47 ~0.53 |

0.54 ~0.64 |

0.65 ~0.70 |

0.71 ~0.80 |

|

Moisture, % (w /w ) |

≤0.05 |

≤0.05 |

≤0.05 |

≤0.05 |

|

Peroxide content (as H2O2 ), %/ (w /w) |

≤0.04 |

≤0.05 |

≤0.05 |

≤0.05 |

|

Average Molecule weight, g/mol |

3800 ~4600 |

3300 ~4100 |

3000 ~3600 |

2700 ~3300 |

|

Viscosity at 40℃, Pa.s |

≤9.0 |

≤8.5 |

≤4.0 |

≤3.5 |

3.SPECIFICATION, Part II:

| PROPERTIES |

SPECIFICATION |

||

|

Hydroxyl content mmol /g |

0.75 ~0.85 |

0.86~1.0 |

1.0 ~1.4 |

|

Moisture, % (w /w ) |

≤0.05 |

≤0.05 |

≤0.05 |

|

Peroxide content (as H2O2 ), %/ (w /w) |

≤0.05 |

≤0.05 |

≤0.09 |

|

Average Molecule weight, g/mol |

2800 ~3500 |

2200 ~3000 |

1800~2600 |

|

Viscosity at 25℃, Pa.s |

4~8 |

2~6 |

2~5 |

Notes

1) all the technical data indicated above are for your reference.

2) alternative specification is welcome for further discussion.

4. Usage: HTPB is widely used in all sort of motor with solid chemical propellant in the aviation and space flight, gunpowder adhesive, also for civil use, it can be used in the fields including PU products, casting elastomer products, paints, electrical insulated sealant materials etc.

5. Net weight 170kg in 200 liters polyethylenelined metal drum.

Customization

Customized manufacturing is available for various application based on your technical requirement.

We have rich experienced R&D, and production department, capable of developing and trial-producing new material and specification as per the specific requirement.

For more information, please send an email to “pingguiyi@163.com”.